About

I am a Product Development Scientist at PharmaLogic which is a radiopharmaceutical company that manufactures and supplies imaging drugs, as well as therapeutic drugs, to hospitals and clinics in the USA and Canada. Trained as a PET radiochemist, I'm involved in drug development that requires my analytical chemistry background and result-oriented perspectives.

The manufacturing facility of PharmaLogic located in Aurora, Colorado, allows us to produce PET isotopes such as F-18 and C-11 via the powerhouse Siemens Eclipse RD Cyclotron which is an 11-MeV, negative-ion, single-particle accelerator. Close to downtown Denver, our site produces a daily average of 82 doses of [F-18] FDG catering to the Denver metropolitan area. We are among the new PharmaLogic manufacturing locations attached to a university hospital, that is, the University of Colorado Anschutz Medical Campus or UCAMC . As our facility is located on campus, we directly supply UCAMC with a very short half-life drugs called [C-11] Acetate and [Ga-68] PSMA as per request. Also, we constantly collaborate with drug companies within the US and abroad to provide infrastructures for drug development and manufacturing in compliance with FDA guidelines. We are proud to be part of GE HeathCare as a developer and producer of their imaging drugs such as Flurpiridaz and Flutemetamol. A recently FDA-approved drug, PyLarify, is also included in our drug portfolio that was developed and produced at our site in collaboration with Lantheus.

Our production laboratory is well equipped with two HPLC (Agilent 1260) and three GC (Agilent 8890) instruments to enhance our quality control capabilities. In addition, we have four synthesizer units (GE FASTLab and TRASIS AIO) which are managed and maintained by our highly qualified PET operators and engineers.

I have played a role in mentoring new staff with different science backgrounds. Working in a fast-paced environment like ours, one works within strict production time constraints when analyzing a drug product that has a short half-life. The kind of support that I’ve practiced at work is to let mentees know that there is always time to step back and take a deep breath. I always remind them that staying calm and focused strengthens their ability to move forward while facing inevitable challenges.

Dr. Melchor Cantorias

A highly motivated chemistry professional with a variety of diverse experience in cGMP processes, radiolabeling of small and large molecules using automated synthesis, radio-TLC and radio-HPLC protocols, as well as product formulation to support discovery and development of radio-tracers used as imaging biomarkers.

Employed and trained at prestigious universities and hospitals, including Columbia University, Cornell University, and Memorial Sloan Kettering Cancer Center.

- Degree: Ph.D. Chemistry

- Website: https://melcan.netlify.app

- Email:mcantorias@radiopharmacy.com

- Phone: (646) 538-3988

- City: Aurora, CO

Skills

Resume

Education

Ph.D. in Analytical Chemistry

The Graduate Center of the City University of New York, NY, NY

Professional Experience

Product Development Specialist

July 2022 - Present

PharmaLogic, Aurora, CO

- Provide technical support to PET drug manufacturing team by using analysis and experience resulting in a 10 percent decrease of errors monthly.

- Interface with drug product sponsors and stakeholders on a weekly Teams meeting to provide updates on projects concerning product development and technology transfer into the PharmaLogic's network.

- Assist in validating HPLC and GC protocols and techniques for newly acquired drugs based on US Pharmacopeia and ICH Guidelines resulting in a streamlined process for validation.

- Create standard operating procedures based on empirical approach that facilitates workflow in the lab.

- Device and validate working spreadsheet to calculate half-life, radioactive concentration at end of synthesis, specific activity, and residual solvent concentration eliminating manual calculation errors which leads to increased productivity.

- Synthesize and perform quality control on Zr-89 DFO-conjugated minibody with high specific activity and percent yield to support Phase III clinical trials.

- Conduct testing on immunoreactivity of CD8 immunoPET imaging drugs via Protein A medium beads, blocking and binding buffers to ensure quality of final products.

- Analyze various metals that may be present in cyclotron-produced radioisotopes using ICP-OES technique to increase efficiency in our production facility.

PET Radiochemist

Apr 2020 - Jun 2022

PharmaLogic, Gray, TN

- Performed PET production of radio-tracers such as F-18 FDG, N-13 ammonia, F-18 Fluoride, Flurpiridaz, Vizamyl, PyLarify to address the need of imaging drugs in Eastern TN and VA regions.

- Operated and maintained automated radiochemistry synthesis devices which optimized production outcomes.

- Followed all SOP guidelines for QC release testing of radiopharmaceutical product, raw material, finished and semi-finished product, environment and facilities to promote good laboratory and manufacturing processes.

- Maintained clean and safe work environment, performing radiation safety duties in compliance with safety and pharmaceutical regulations.

- Accomplished other job-related duties as assigned allowing to diversify skills and techniques, thus, creating opportunities for collaboration with other departments.

Visiting Scientist

Jan 2020 - Mar 2020

Lehman College, Bronx, NY

- Updated and redesigned the LC-MS protocol to facilitate the use of the Agilent UPLC-QToF.

- Explored into the realm of plant-derived biomarkers as potential for imaging.

- Created and managed a website for the lab.

Production Radiochemist

Oct 2018 - Dec 2019

NCM-USA, Bronx, NY

- Coordinated schedules with cyclotron engineer, pharmacist and QA officer in the production and delivery of the brain imaging drug called Flortaucipir (AV151).

- Produced an average of 16 imaging drugs per week supporting phase III clinical trials performed in the East Coast region(eg. Yale, UPenn, General Massachusetts, NYU, Columbia, etc.). Our facility was also a stand-by supplier for clinics in Quebec region.

- Prepared materials and performed aseptic vial-assembly operations in cleanroom.

- Carried out sample dosing in hot cell compartment using remote manipulators.

- Monitored and evaluated bacterial growth for cleanroom and isolator confidence.

- Performed root cause analysis to avoid interruptions/delays in work flow.

- Conducted regular training for new staff to qualify for cGMP-tailored protocols in proper handling of radioactive materials and use of automated synthesis modules.

Associate Research Scientist

Oct 2014 - Sep 2018

Columbia University Medical Center, New York, NY

- Performed automated routine synthesis of cGMP-compliant C-11 radiotracers such as CUMI, DASB, PiB, RAC, PBR, and PHNO, and F-18 radiotracers such as NOP and choline.

- Produced abbreviated new drug application (ANDA) PET drugs such as N-13 ammonia, requiring basic operation of Siemens Eclipse cyclotron.

- Performed quality control processes in accordance with FDA PET cGMP and USP <797> guidelines.

- Performed radio-metabolite tracer experiments including blood sample processing and HPLC analysis.

- Assisted in preparation and review of standard operating procedures, chemistry manufacturing and controls (CMC) and other regulatory documents.

- Certified in the following: (1) HIPAA Compliance, (2) DOT Class 7 Radioactive Material Shipping, (3) Annual Radiation Safety, (4) Lab Safety, Chemical Hygiene, and Hazardous Waste Management, (5) Bloodborne Pathogens/Infection Control Training for Personnel in Human Research Studies and Clinical Settings.

Additional Experience

- Research Associate, Weill Cornell Medicine, NY, NY

- Research Fellow, Memorial Sloan Kettering Cancer Center, NY, NY

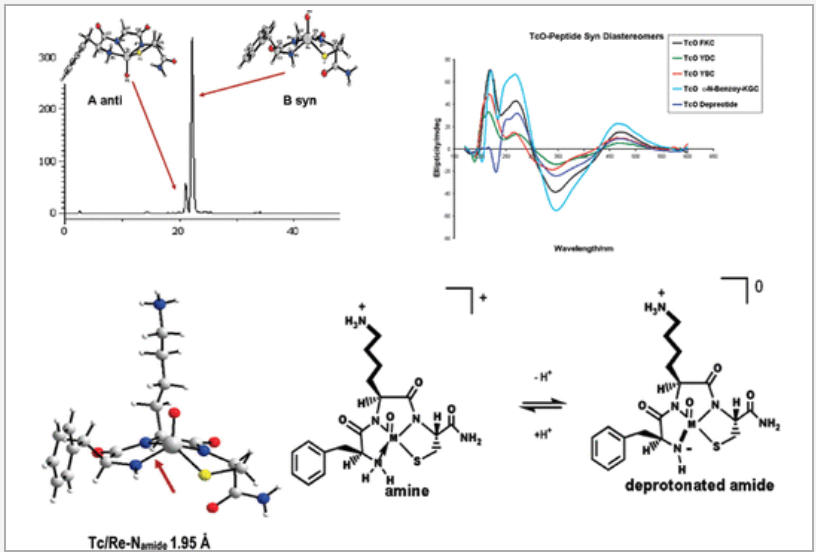

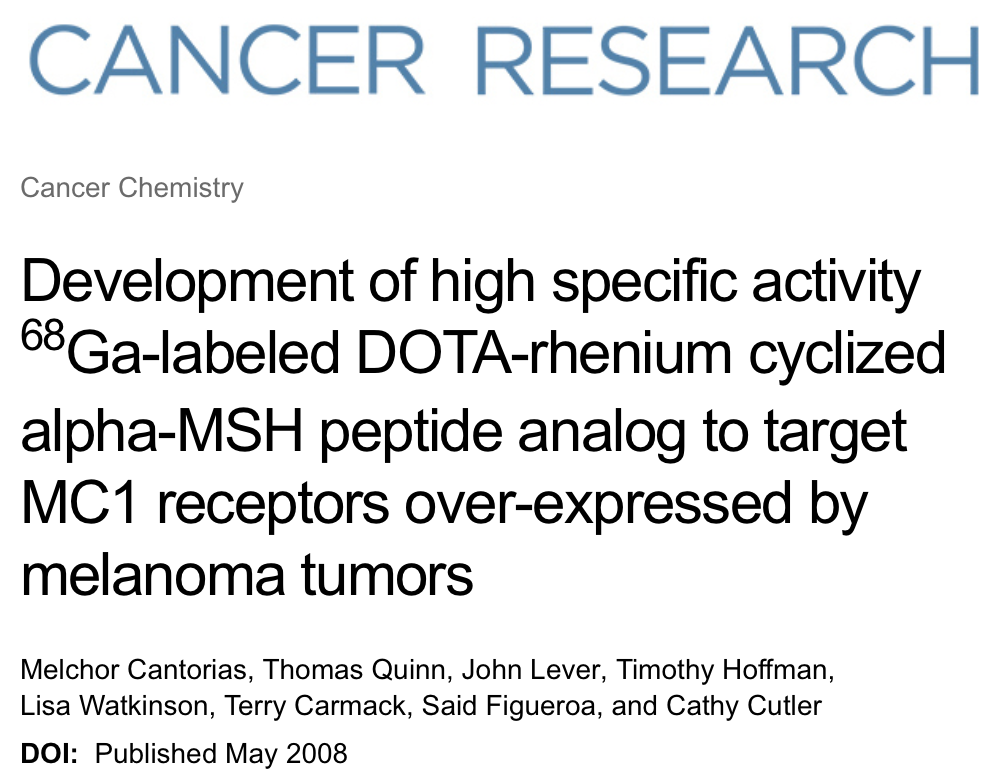

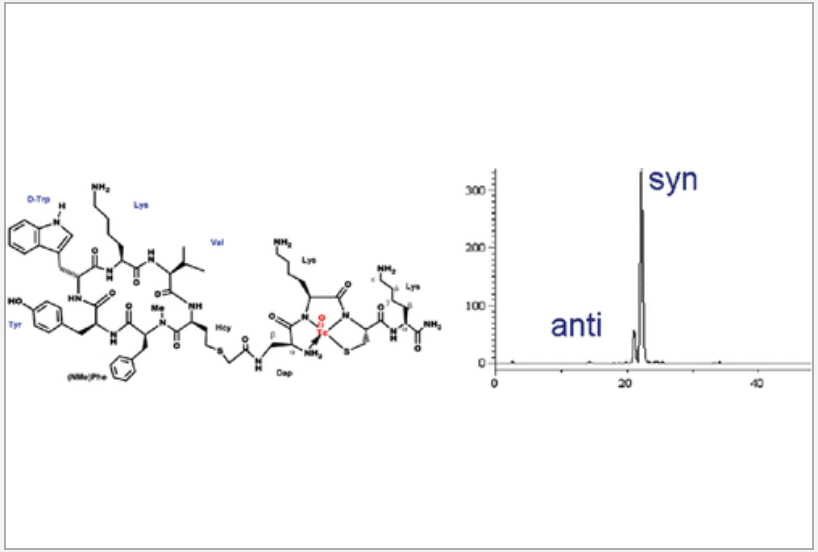

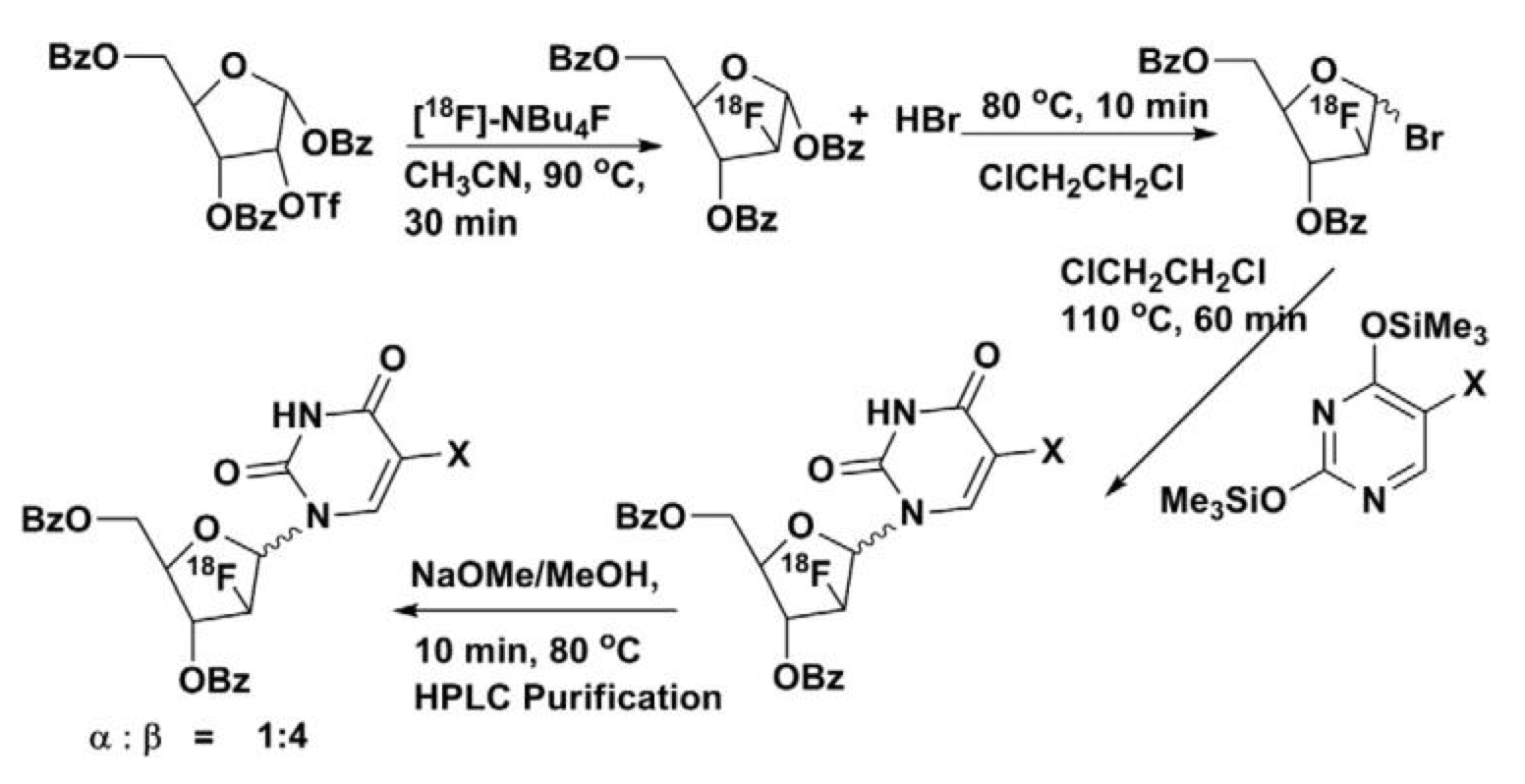

- Postdoctoral Fellow, University of Missouri Research Reactor Center, Columbia, MO

- Teaching Assistant, Hunter College, NY, NY

Research and Selected Publications

- All

- Research

- Publications

The Research and Development Infrastructures at PharmaLogic

The Aurora site is the only manufacturing facility unique to all PharmaLogic locations. We have a laboratory unit dedicated only to research and development. Our in-house scientists work around the clock to implement various studies that involve radiolabeling of bioactive molecules with Zr- 89 and I-125. The laboratory is also equipped with Agilent 1260 HPLC and 8890 GC. We utilize these instruments in developing and validating HPLC and GC protocols for newly developed drugs. Our laminar hood and two hot cell units provide a convenient environment for handling both low and high level millicuries used for experimental radiochemistry synthesis. We have one mini TRASIS unit housed in one of these hot cells that can be used for synthesis automation. Presently, PharmaLogic and ImaginAb are working together to automate the synthesis of Zr-89 IAB, a radiolabeled antibody that can function both as a diagnostic and therapy without changing the radioactive isotope. In addition, the manufacturing of [Zr-89] IAB via non-automation synthesis has already been validated and approved to support the ongoing Phase I clinical trials. Another company, Telix, based in Australia, is also joining us for implementing their drug synthesis automation.

PharmaLogic has recently acquired an Agilent ICP-OES (Inductively Coupled Plasma – Optical Emission Spectroscopy) unit to bolster our drug development program. As our company continues to grow, we envision making more medically applied radioisotopes available in our cyclotron facility such as Ga-68 and Zr-89. The ability to examine metal contamination in cyclotron-produced isotopes with the use of ICP-OES technique is an unmet goal that we want to achieve in the next few years.

Testimonials

Contact

Thank your for visiting my website! If you have any queries on my research work or non-related job interests (running, coffee and beer brewing 😊), please write in the message section below and I'll be happy to write back!

Location:

2115 N Scranton St. Suite 1065, Bioscience Building #3, Anschutz, Aurora, CO 80045

Email:

mcantorias@radiopharmacy.com

Call:

+1 646 538 3988